|

|

|

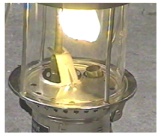

The PETROMAX Multi-Fuel Lantern

"PETROMAX" lanterns were designed and developed

by Adolf & Max Graetz, who were appointed managing directors of their family business (Ehrich & Graetz) in 1889.

From their efforts arose the most powerful

& reliable lanterns in the world. Petromax lanterns run on a variety of fuels.... kerosene, alcohol-based fuels, mineral

spirits, citronella oil, gasoline, diesel oil, & almost every flammable fuel available on the market.

The first lanterns developed, named Petromax,

were used by the German army before and during World War Two. The military significance of a lantern that would burn all liquid

fuels from diesel oil to gasoline made the lantern very useful. Also developed were heaters and stoves. These three items

gave the German army the benefit of heat, light and a way to prepare food with the use of any liquid fuel available.

The German army and many other military service

including NATO forces still use the same product line of the original company. All of the lanterns, stoves and heaters used

today, by the general public world wide, are known to be reliable and easy to repair. With the use of kerosene as the fuel

of choice, this lantern has a problem free life of decades if a little tender loving care is bestowed upon it.

Gas Mantles are used in Petromax Lanterns for

lighting and heating purpose. The light intensity of Gas Mantles is either defined in LUX or CANDLE POWER, shortly abbreviated,

as C.P. Gas Mantles are available from 100 C.P. to 1000 C.P. However the most popularly used are 300-400 C.P. and 400-500

C.P.

We are in this line of manufacturing gas mantles

since 1960 and we are the registered trademark owners of the popular brands like Kanhaiya Gas Mantles and Rahi Gas Mantles

to our credit widely being used in India and abroad. We do and we can tailor make Gas Mantle in any Candle Power.

For more information contact:

ILYAS YUSUF MAKANI ilyasmakani@yahoo.com

YUSUF PRODUCTS

17/D, Memonwada Road, Mumbai: 400 003.

India.

Phones: (91)(22) 23454698, 23723564.

Fax: (91)(22)

23746242.

www.muby.itgo.com

|

|

Gas Mantle

An incandescent gas mantle, gas

mantle, or Welsbach mantle is a device for generating bright white light when heated by a flame. The name refers

to its original heat source, existing gas- lights, which filled the streets of Europe and North America in the late 19th century,

mantle referring to the way it was hung above the flame. Today they are still used for portable camping lanterns and pressure

lamps.

They work by utilising the heat of a flame,

in modern portable applications produced using kerosene or LPG, to heat them up to around 1000 degrees celsius. At this temperature

they are sufficiently hot to radiate an intense white light as a consequence of the spectral lines of rare earth elements

in the mantle. The light is not produced through black body radiation since the temperature is too low to generate white light.

Modern mantles are made of ramie-based artificial

silk or rayon. When the mantle, a small net bag, is attached to the lamp and used for the first time, the heat burns away

the cellulose of the bag and converts the rare earth nitrates soaked into it into a rigid, but very fragile, structure made

of metal oxides.

Since thorium is radioactive, and produces

a radioactive gas, radon-220 as one of its decay products there are concerns about the safety of thorium mantles. Some nuclear

safety agencies make recommendations about their use. A study in 1981 estimated that the dose from using a thorium mantle

every weekend for a year would be 0.3-0.6 millirems, tiny in comparison to the normal annual dose of a few hundred millirems

although a person ingesting an entire mantle would receive a comparable dose of 200 mrem. However the radioactivity is a major

concern for those people involved with the manufacture of mantles, and with contamination of soil around some former factory

sites. All of these issues have meant that alternatives, usually yttrium or sometimes zirconium, are used in some countries

although they are either more expensive or less efficient.

|

|

History

For centuries, artificial light had been generated using open flames. Limelight had been invented in

the 1820s but the temperature required was too high to be practical for small lights. In the late 19th Century several inventors

tried to develop an effective alternative based on heating a material to a lower temperature but using spectral lines to simulate

white light.

Many early attempts used platinum / iridium gauzes soaked in the metal nitrates, but were not successful because

of the high cost of the materials and poor reliability. The first effective mantle was the Clamond basket in 1881,

named after its inventor. It was exhibited in the Crystal Palace exhibition of 1883. This device was made from a mixture of

magnesium hydrate, magnesium acetate and water which was squeezed through holes in a plate to form threads, which were then

moulded into a basket shape and ignited. The acetate burnt, the combustion products forming a matrix to support the magnesium

oxide formed as the hydrate decomposed. The fragile structure was supported by a platinum wire cage and heated by a coal gas

flame.

The modern gas mantle was one of the many inventions of Carl Auer von Welsbach, a chemist who studied rare earth

elements in the 1880s and who had been a student of Robert Bunsen. His first process used a mixture of 60 percent magnesium

oxide, 20 percent lanthanum oxide and 20 percent yttrium oxide, which he called Actinophor, and patented in 1885.

The original mantles gave off a green-tinted light and were not very successful, and his first company, which

established a factory in Atzgersdorf in 1887, failed in 1889. In 1890 he discovered that thorium

was superior to magnesium, and in 1891 perfected a new mixture of 99 percent thorium dioxide and 1 percent cerium dioxide

gave off a much "whiter" light, and the thorium oxide added considerably to the strength of the mantle. After introducing

it commercially in 1892 it quickly spread throughout Europe. The gas mantle remained an important part of street lighting

until the widespread introduction of electric lighting in the early 1900s.

To produce a mantle, cotton is woven into a net bag and impregnated with the soluble nitrates of these metals

and then heated; the cotton burns away and the nitrates are converted to nitrites that fuse together to form the solid mesh.

As the heating continues, the nitrites decompose into the final solid, (but fragile) very high melting point oxides.

Early mantles were sold in the unheated cotton mesh condition, since the oxide structure was too fragile to

transport easily and the purchaser carried out the conversion when it was first used. The cotton quickly rotted because of

the corrosive nature of the acidic metal nitrates (although was later reduced by soaking the mantle in ammonia solution to

neutralise the excess acid).

Later mantles were made from guncotton or collodian rather than ordinary cotton, since extremely fine threads

of it could be produced; it was converted back to cellulose before heating (since these materials are highly flammable or

explosive) by dipping in ammonium sulfide.

It was discovered that the finished mantle could be strengthened sufficiently by dipping in a solution of collodion

which would coat it with a thin layer of the material to be burnt off when the mantle was first used, although modern mantles

are now usually sold in their original fabric condition. Early

mantles often had a binding thread of asbestos for tying onto the lamp fitting, but because of its carcinogenic properties

it has been replaced with wire in modern mantles.

|

|

|

|

FEW FACTS ABOUT GAS MANTLES

A

Gas Mantle is a device that gives of considerable light when heated. The name refers to its original power source, existing

gaslights, which filled the streets of Europe and North America in the late 19th Century mantle, referring to the

way it hung above the flame. Gas Mantles are still being used in Uttar Pradesh and Bihar in India, Afghanistan, Pakistan and

Bangladesh. The gas mantle was one of the many inventions of Auer von Welsbach, a chemist who studied rare earth element in

1880. His first process used a mixture of 60% Magnesium Oxide, 20% Lanthanum Oxide and 20% Yttrium Oxide, which he called

Actinophor. To produce a mantle guncotton is impregnated with the mixture and then heated, the cotton burns away leaving a

solid, but fragile mesh of ash. These original mantles gave off a green tinted light and were not very successful, and his

first company formed to sell them failed in 1889. A new mixture of 99% Thorium Oxide and 1% Cerium Oxide gave off much whiter

light, and after introducing it commercially in 1892 it quickly spread through out Europe. The gas mantle remained an important

part of street lighting until the wide spread of electric lighting in early 1900. A mantle is basically a small sock made

of silk or asbestos. Asbestos can withstand high temperatures, but is also toxic. Silk-based mantles are extremely brittle

once first burnt and must be replaced frequently. Thorium is radioactive, and Pure Thorium becomes more radioactive as it

ages owing to its decay products. It should be handled with care. Owing to concerns about radioactivity, alternatives are

now used in some countries, but these are more expensive and less efficient. Though studies conducted by the members of Indian

Gas Mantle Manufacturers Association in Northern Parts of India have shown that use of thorium based gas mantle is not a health

hazard due to negligible amount of Thorium content in each gas mantle. The negligible Thorium content also make it non hazardous

to environment as well. However to make non radioactive gas mantle a mixture of Yttrium Nitrate and Europium Nitrate is used

on a woven sock of man made rayon.

Our

belief in Gandhiji's Theory

"A customer is the most important visitor on our premises. He is not dependent on us. We are dependent

on him. He is not an interruption of our work. He is the purpose of it. He is not an outsider to our

business. He is part of it. We are not doing him a favour by serving him. He is doing us a favour by

giving us the opportunity to do so."

(Mahatma Gandhi 1869-1948)

|

|

|

|

|

|

For Clacium Chloride, Zinc Chloride and Phase

Change Materials write to

Simrone Products, S-8, Sarifa Mansion, Second Flank Road, Mumbai: 400009. India.

For our Chemical Division

http://www.pcmenergy.com/

YUSUF PRODUCTS

17/D, Memonwada Road, Mumbai: 400 003. India

|

|

|

|